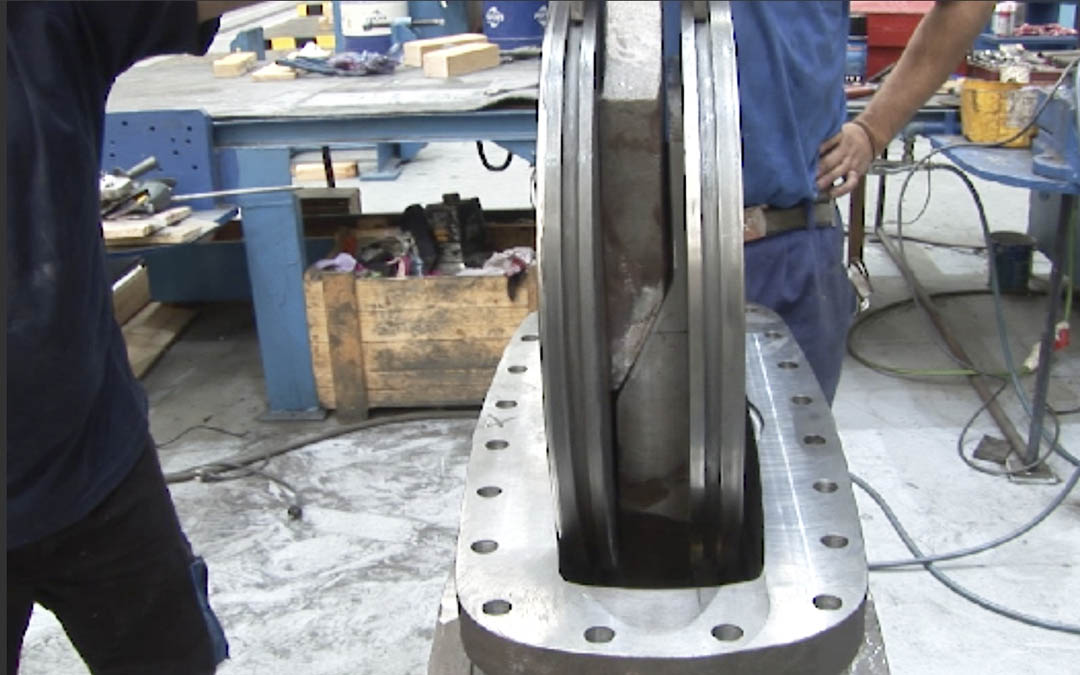

Babcock supplies a 20” double wedge and double disc gate valve operated by electric actuator, for a special requirement received from a PETRONAS Refinery in Malaysia.

Babcock supplies a 20” double wedge and double disc gate valve operated by electric actuator, for a special requirement received from a PETRONAS Refinery in Malaysia. This special design permits that the sealing load increases as the differential pressure across the disc increases too, thus providing a tight seal throughout the entire range of operating differential pressures. Since the discs are independent of each other and the design is symmetrical, positive sealing can be maintained in either direction.