by Babcock's communication | Mar 12, 2024 | News

Currently, we are manufacturing seismic-qualified variants of Bellows seal valves designed in accordance with ASME Section III for a Nuclear Power Plant. Before providing a glimpse into our workshop, please find below a concise introduction to these specialized...

by Babcock's communication | Mar 5, 2024 | News

Step into the world of precision and collaboration as we showcase the meticulous process of hydrotesting a 10″ ANSI Class 2500# A217 WC9 alloy steel Wedge Gate valve in our state-of-the-art facility. Our commitment to excellence is evident in the seamless...

by Babcock's communication | Feb 27, 2024 | News

In older posts we wrote about valves in steam boiler systems, including CBD and IBD types. This time we revisit the significance of Intermittent Blow Down (IBD) valves. The IBD valve plays a pivotal role, tasked with expelling dissolved salts, mud, and solids settled...

by Babcock's communication | Feb 20, 2024 | News

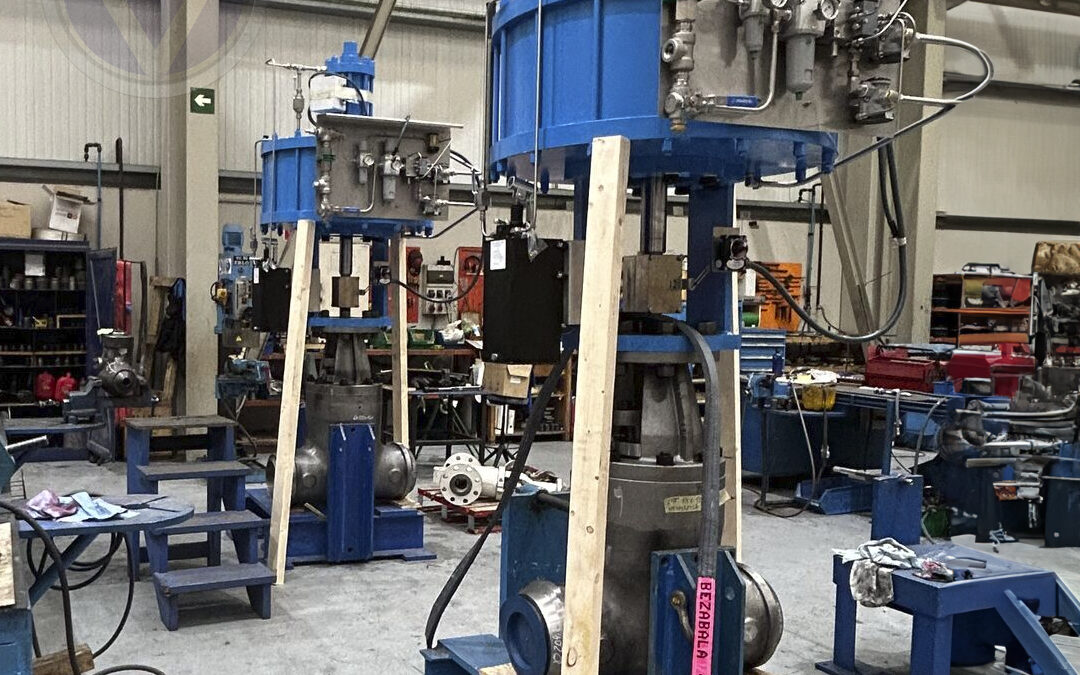

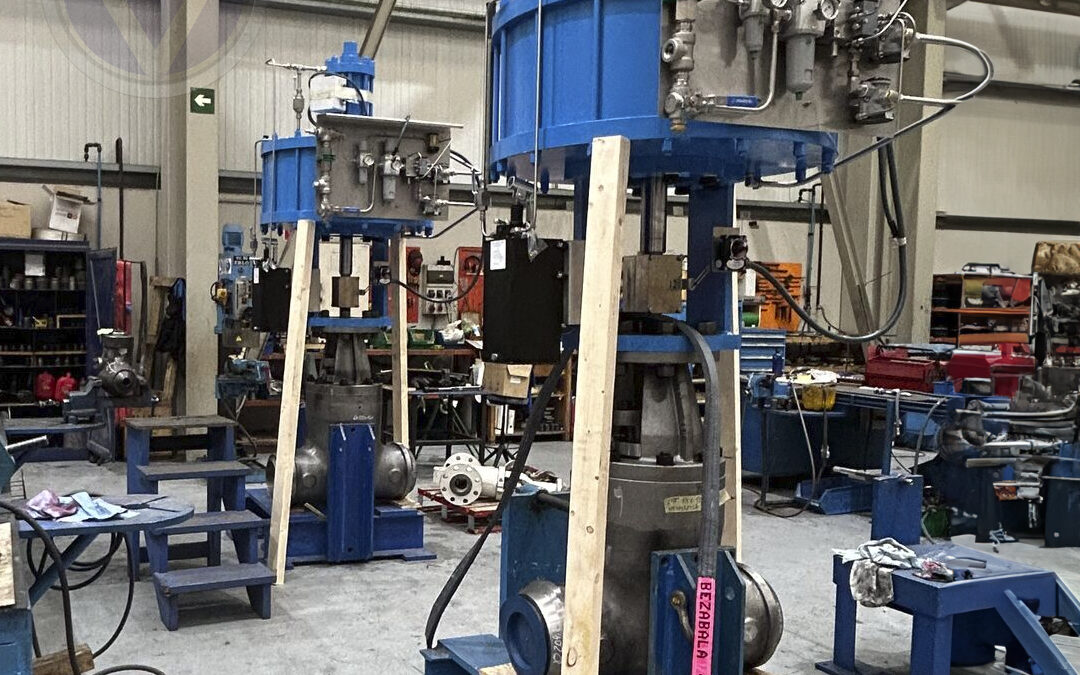

Doesn’t it seem like an extensive testing setup for a standard 800# valve? Welcome to a snapshot of our collaborative workshop efforts at Babcock Valves. Our testing facilities range from small to medium-sized, with a standout—one of the largest in Europe....

by Babcock's communication | Feb 13, 2024 | News

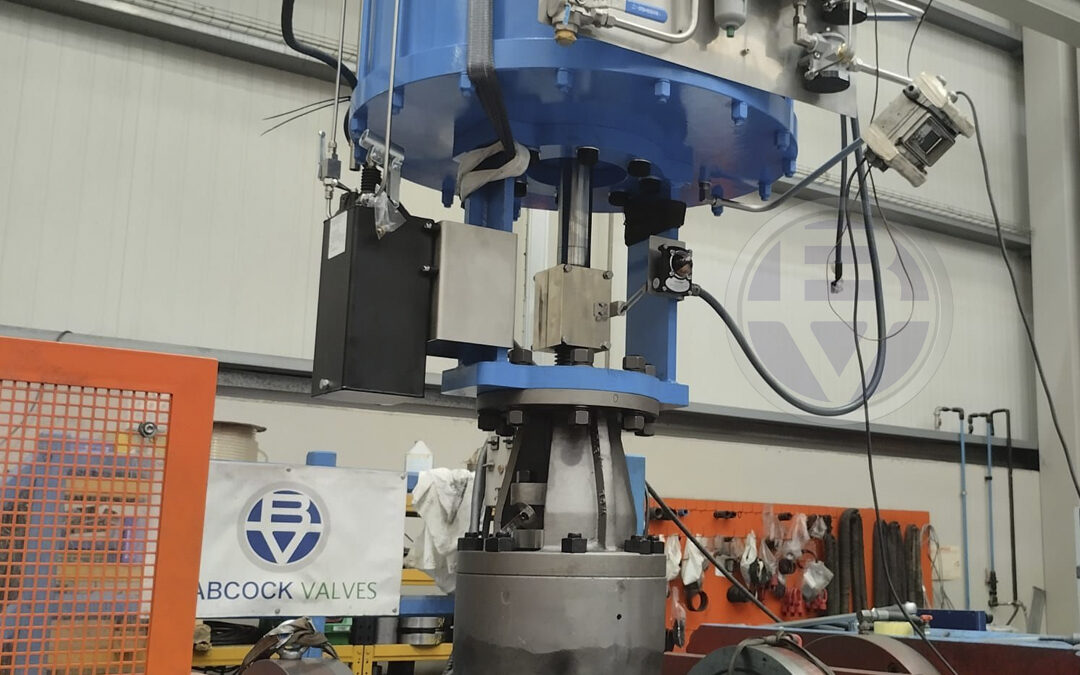

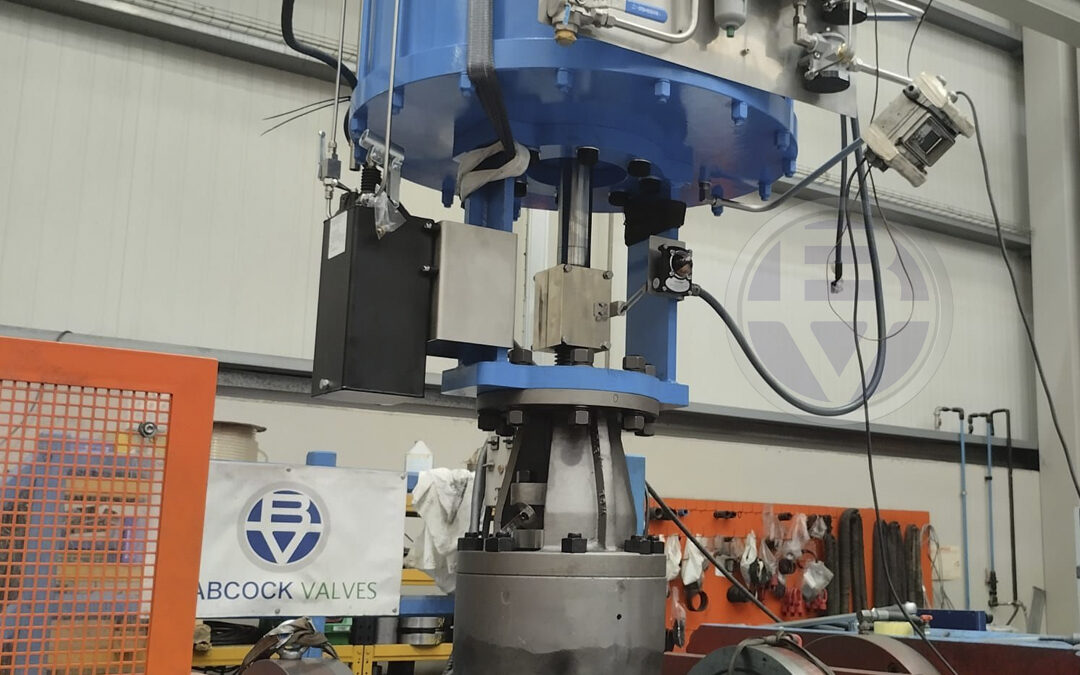

This picture taken in our workshop, witness the final assembly stage of a pair of High-Pressure Gate Valves equipped with pneumatic instrumentation. This collaborative effort involves one of our approved Spanish partners, specialized in actuators. The precision in...

by Babcock's communication | Feb 6, 2024 | News

In a recent update on our operations, we provided an insight into the meticulous assembly process of a robust 16″ 4500# A182 F92 Parallel Slide Gate Valve. Today, we delve deeper into the features that make Parallel Slide Gate Valves indispensable in various...