by Babcock's communication | Dec 20, 2023 | News

by Babcock's communication | Dec 19, 2023 | News

We showed you in a prior post some actuator driving bushes ready to be internally machined. Just the valve stem and the actuator driving bush machining will define the valve operation time in the ON-OFF valves and the regulation precision level in all flow control...

by Babcock's communication | Dec 12, 2023 | News

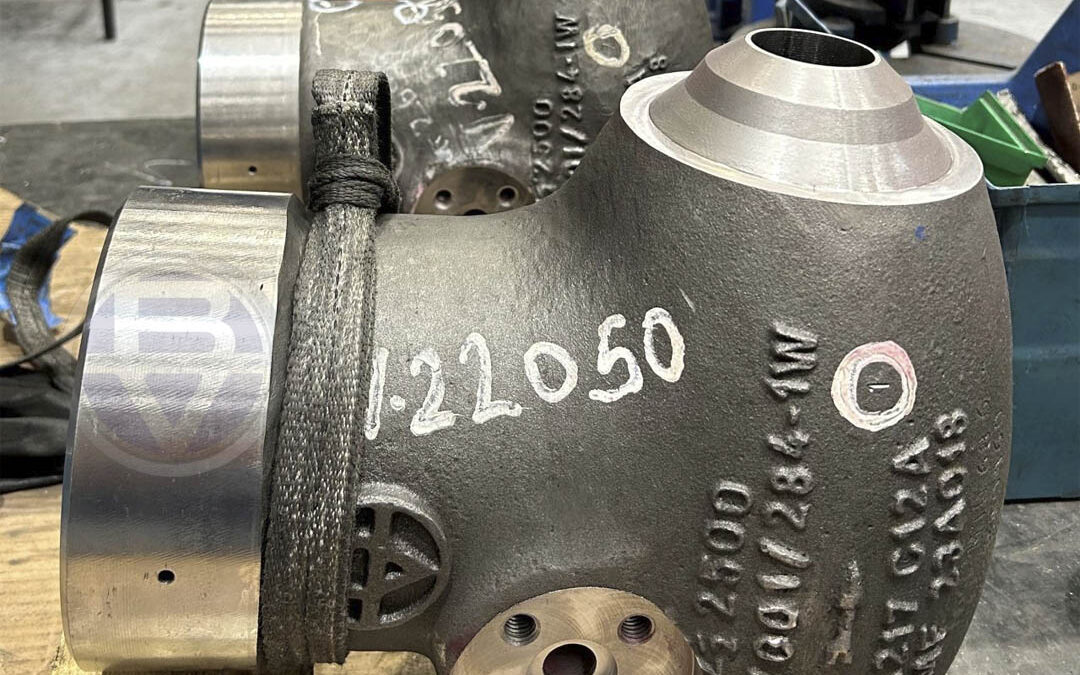

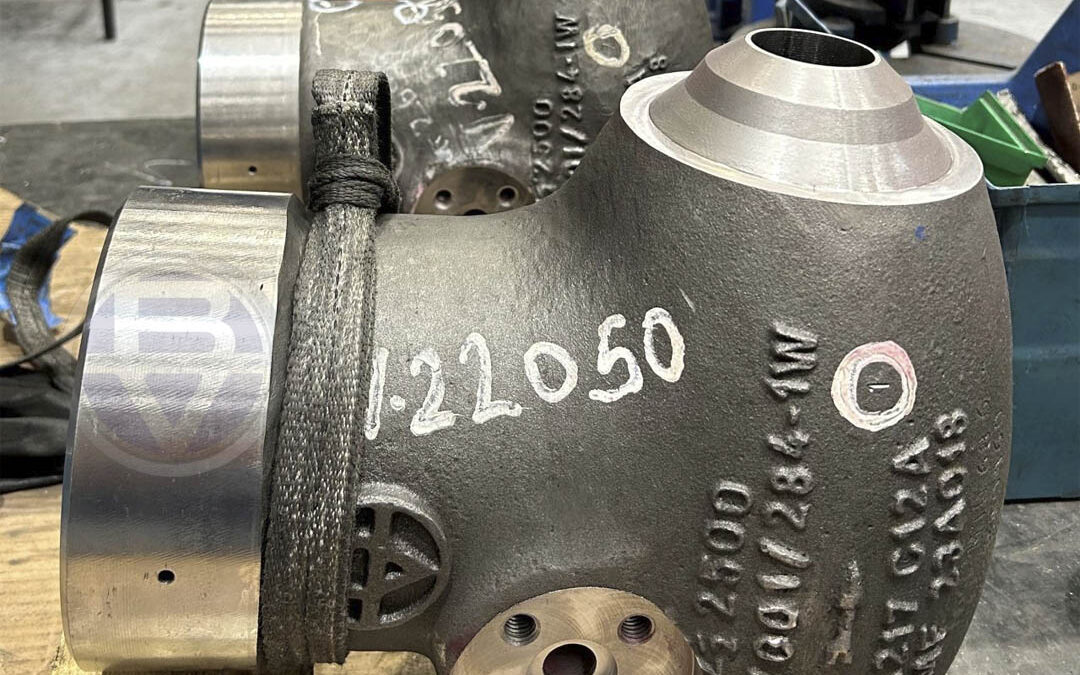

Here we have, in our medium-size test bench (a 450 Tons one) a Triple eccentric Butterfly valve being tested. Rating according to ANSI Class 2500#; stainless steel body (ASTM A351 CF10 casting); trim no.12 (316/hard-faced), metal to metal seating, shafts in Stainless...

by Babcock's communication | Dec 5, 2023 | News

Meet these twin valves. After passing through their first stages of life (melt in the foundry, NDE, reception, acceptance, machining), these twin check valve sisters begins one of the most amazing one: the assembly process. In this phase, they will meet all internals,...

by Babcock's communication | Nov 28, 2023 | News

Here we have a DN65 (2 ½”) ANSI Class 2500# High Alloy A217 C12A swing check valve during body inspection, performing a PT test. Valve body inspections help ensure compliance with industry standards and regulations. Valves are often subjected to specific design codes,...

by Babcock's communication | Nov 21, 2023 | News

At Babcock Valves all valves are important: nuclear-qualified valves with ASME Section III design, Low Emission Bellows Seal valves Helium tested, Steam Extraction Quick Closing Check valves for turbine protection, Instrumented valves both MOV, AOV or Hydraulically...