Combines the strenght of its components with a dependable and compact design.

Babcock ball valves satisfy a wide range of ASME, ANSI and API standards. Available in cast steel and forged steel, with various trims, they may be specified in sizes from 1/4″ to 60″, and pressure classes of 150 through 2500.

Engineered for heavy duty, maintenance-free performance, the BV ball valve is commonly selected for a number of demanding applications, being considered one of the most trusted valves in the petroleum and chemical process industries.

Product Range

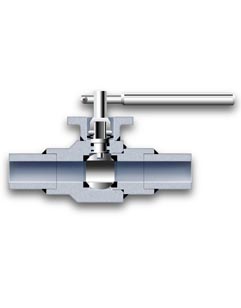

Code BFI

Type: Floating Ball Side Entry

Body: One Piece

Sizes: 1/2″- 3″

ANSI Class: 150-900

A simple design with a good sealing performance for low and middle pressure applications.

Floating ball valves uses natural line pressure to press and seal the ball against the downstream seat.

To avoid the deformation of sealing ring due the workloads it withstands, our designs increase the contact area between the ball and the sealing ring, reducing the sealing pressure.

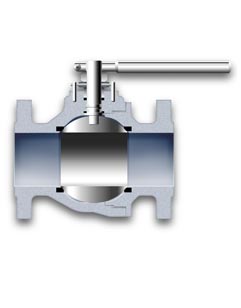

Code BFR

Type: Floating Ball Side Entry

Body: Threaded & Sealed

Sizes: 1/2″- 12″

ANSI Class: 150-900

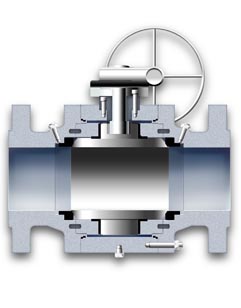

Trunnion design for dependable low torque operation.

Babcock Trunnion ball valves have floating seats that move with the medium pressure to tight the ball and seal ring to ensure sealing reliability.

Bearings mounted in top shaft and bottom shaft, reduces considerably operation torque. They are mainly used in valves with high pressure and big sizes.

To decrease the operation torque and increase the reliability of the sealing, Babcock ball valves are supplyed with two greasing fittings into both, the upstream and the downstream seat pockets.

SIDE ENTRY

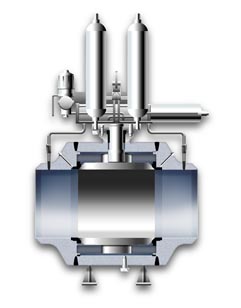

Code BGA

Type: Trunnion-Mounted Side Entry

Body: Bolted

Sizes: 2″- 60″

ANSI Class: 150-1500

WELDED BODY

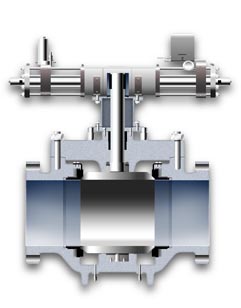

Code BGS

Type: Trunnion-Mounted

Body: Welded Body

Sizes: 2″- 60″

ANSI Class: 150-900

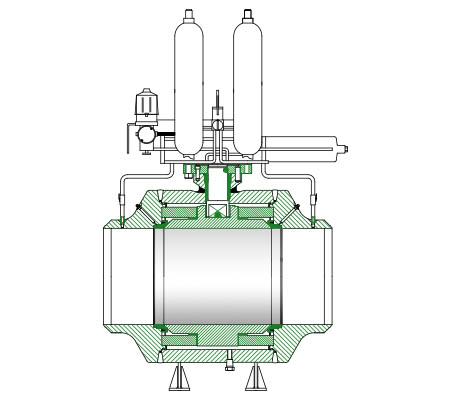

TOP ENTRY

Code BGT

Type: Trunnion-Mounted Top Entry

Body: Bolted Body

Sizes: 2″- 60″

ANSI Class: 150-1500

FEATURES AND BENEFITS

Wide selection seat/seal trims

A wide variety of trims are available to match each valve to its aplication, including metal to metal trims.

Protected seats for long life

The protected seat design features a deep pocket with a protective lip. This design prevents cold flow of the seat into the line. This results in extended seat life over conventional designs.

Large diameter trunnion

Provides smooth, easy operation and extended bearing life. The trunnion bearings are stainless steel with heavy duty PTFE coated.

Actuator mounting brackets

Available as options for users who prefer to install their own actuators. We recommend that buyers specify factory- installed actuators to assure reliable, long life performance.

Bidirectional sealing

Babcock trunnion valves are equipped with pressure-actuated seats offering true bidirectional sealing performance.

Automatic body pressure relief

The pressure actuated seat construction assures positive relief of excess pressure. If the body pressure exceeds the line pressure and seat pre-load pressure, the seat(s) will automatically back off to relieve the excess pressure.

TFM insert

The seat assembly consists of an outer metal seat ring with a TFM insert. The TFM insert locates into a groove in the metal ring. A spring assembly behind the seat loads the seat against the ball and prevents leakage from behind the seat. This efficient seat design provides positive shutoff.

Double block and bleed

The pressure actuated seats of Babcock’s trunnion valves provide a positive up and downstream seal under all conditions. When used for block and bleed, this feature lets the valve to take the place of two valves, allowing the operator to check the up and downstream sealing by installing a pressure releasing tool to bleed body pressure.

Easy to maintain

Babcock valves can be completely disassembled in the field for replacements of seats or a complete overhaul. Seats can be replaced quickly without the need for special tools.

Positive stem retention

Babcock trunnion mounted ball valves are manufactured with true anti blow out stem. The stem is inserted from whitin the valve body and is positively retained whitin the body cavity. This method of stem retention eliminates the need for external locking pins devices, which may be subjected to inadvert removal and the subsequent risks.

Adjustable packing

The stem packing material is graphite. The unique design of the BV stem packing assembly allow full maintainability of the packing material and replacement of FPM o-rings while the valve is in line and in service. This is achiebved by the security of a secondary stem seal located below the packing and upper lantern ring.

Actuators

Babcock valves are suitable for operation by any type of pneumatic, electric, or hydraulic actuators. We offer factory-mounted valve-actuator packages with single source efficiency, responsibility and warranty.

BABCOCK VALVES S.A.

ADDRESS

P.E. Abra Industrial, Parcela 1.5.6 – 48530 Ortuella (Bizkaia) Spain

TELEPHONE

(+34) 944 536 423

FAX

(+34) 944 535 739

Inquiry form

You can send us any question of your interest.

We will get back to you as soon as possible.

Legal disclosures

Cookies policy

Privacy statement