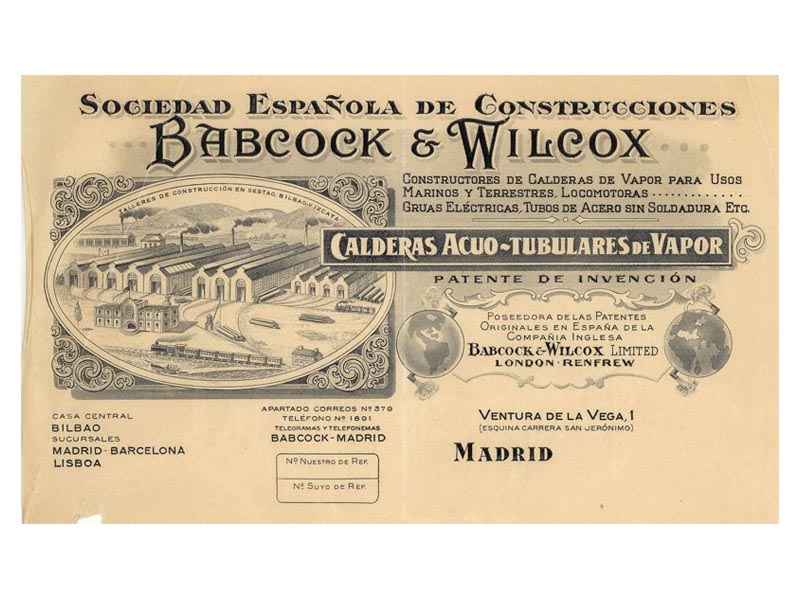

Babcock Wilcox Heritage

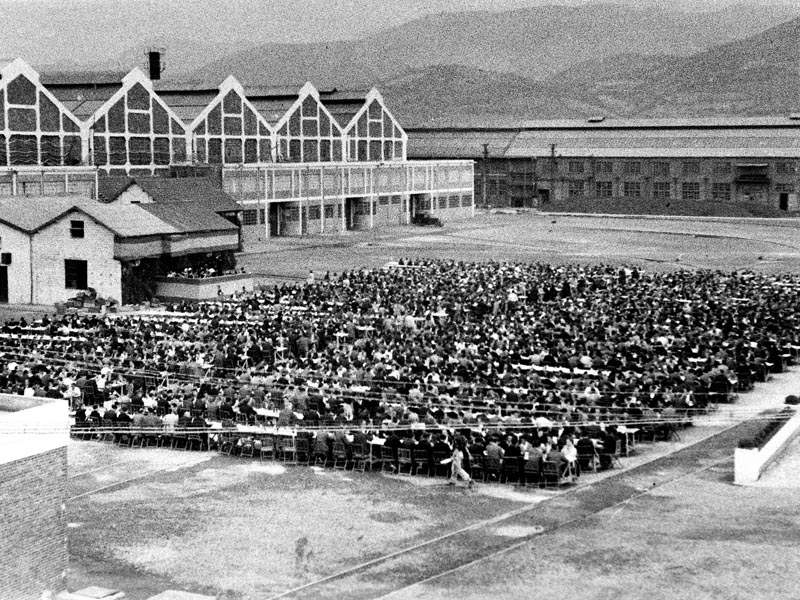

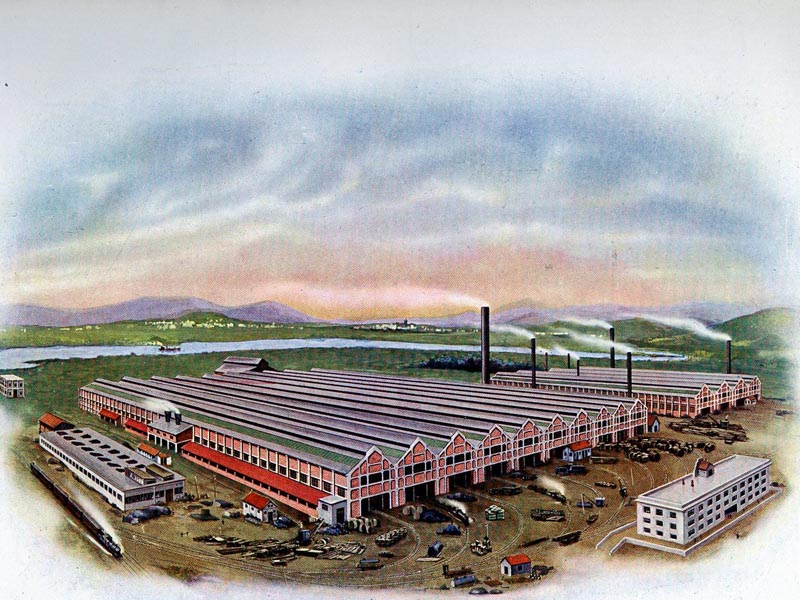

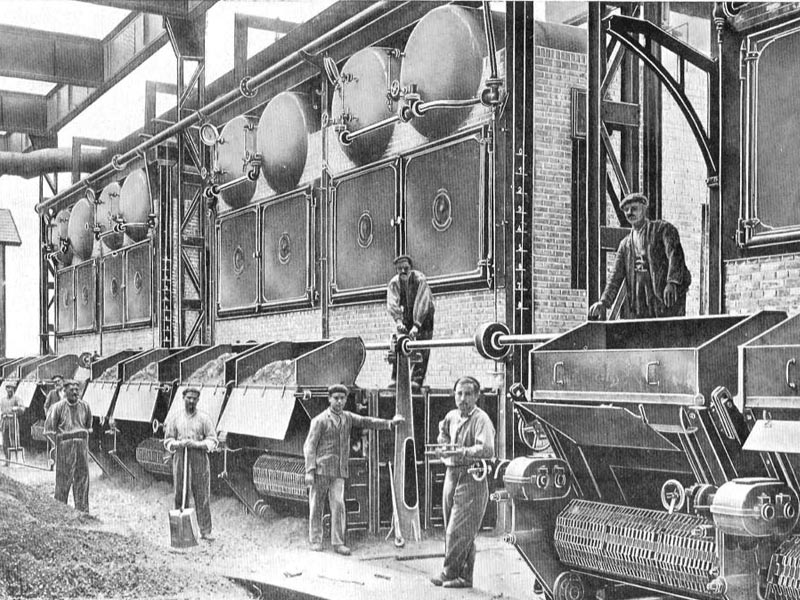

In 1967, Babcock Wilcox Española -present in the Spanish market since 1918- implemented its diversification policy by setting up a valve manufacturing division, which soon became one of the leading players on the international market, thanks to its engineering efforts, developing new designs to improve product reliability in the power generation sector (nuclear and conventional), petrochemical industry, oil & gas sectors and water works.

Babcock Valves has the expertise, the know-how and the industrial experience of a company with almost half a century of history behind it, and a legacy of over 1.250.000 valves installed all around the world.

At Babcock Valves our commitment to our customers is underlined by a combination of tradition and continuous innovation.

Our name is recognized around the world as a benchmark for reliability and service excellence, with hundreds of customers expressing their satisfaction with our supplies, taking advantage of the right performances of our valves for years.

KNOW-HOW + EXPERTISE = BABCOCK VALVES

Engineered to the limit

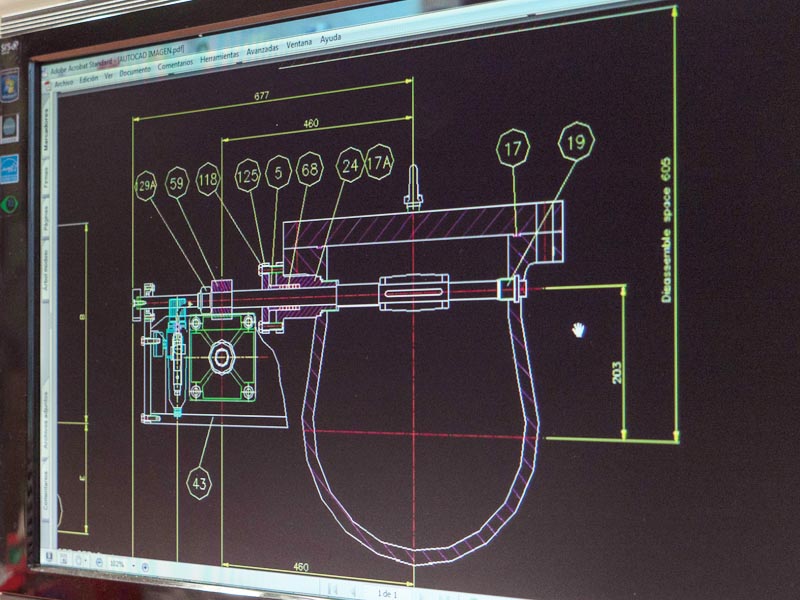

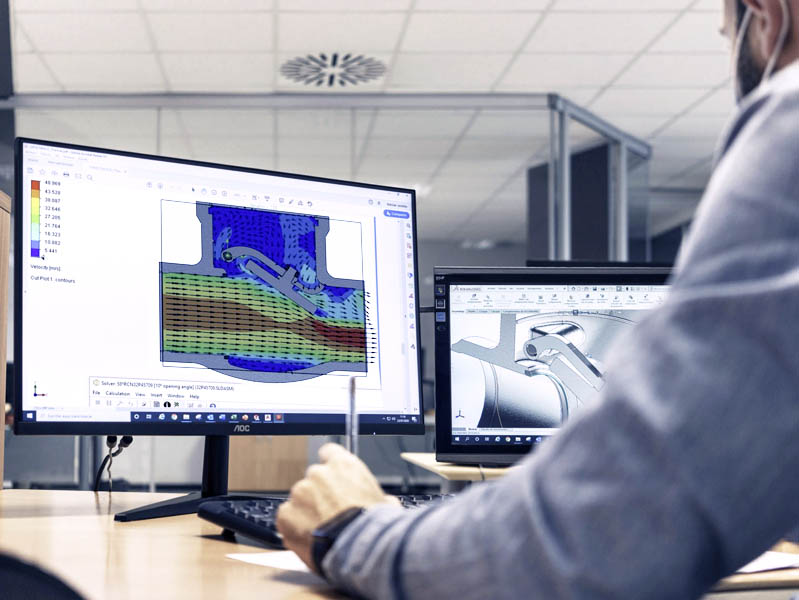

At Babcock Valves we use the latest software tools to develop and improve our own designs, to ensure the products we supply always comply and exceed the latest standards and international regulations.

Babcock Valves’ designs are based on advanced computer simulations, which minimize the possibility of design shortcomings and deficiencies affecting our valves, thereby ensuring our products always meet the latest applicable standards and customer requirements.

Our engineering team can guarantee the quickest possible response to meet our customers’ requirements, anywhere in the world.

Research, Development and Innovation

Babcock Valves has its own Research + Development + innovation department (R+D+i) that works each and every day towards the same goal: how to improve our valves.

In doing so we use the latest software tools and technology to improve our own designs and develop new products, providing our customers with the best technical solutions and obtaining significant advantages over the competitors.

We design our own range of products with special emphasis on safety, low maintenance, long service life and the highest quality, optimizing the entire production process to offer competitive prices.

Our R+D+i team guarantees the quickest response to meet our customer requirements with personalized service.

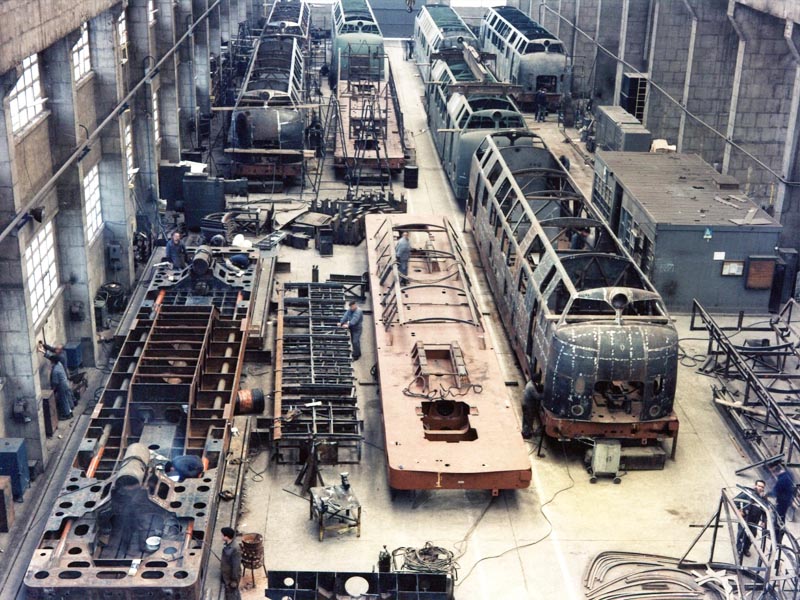

MANUFACTURING PROCESS PLAN (MPP)

The manufacturing process at Babcock Valves is carefully controlled by our Q.A. staff, from receipt of purchase order to dispatch of the goods.

Facilities & suppliers

Each stage of the production process is conducted at own facilities or in cooperation with recognised and approved suppliers.

Casting quality

Casting quality, particularly in the case of alloys, special alloys and exotic materials, is guaranteed by working with foundries equipped with the most advanced production systems plus the Non-Destructive Tests required for each piece.

Experienced staff

Precision machining, including processes such as valve seat and disc lapping, welding or surface hardfacing, are fully controlled by our experienced staff, ensuring that all valve components reach the assembly stage in perfect working condition.

Testing benches

All valves manufactured by Babcock Valves are fully tested at our wide range of testing benches.

Painting

Where required, any painting system can be applied at our facilities.

Long lasting valves

Our goal is to produce zero defects and long-life valves.

AFTER SALES SERVICE

Spare parts

On-site maintenace

Analysis & troubleshooting

Product training

With more than 1.200.000 valves installed all around the world, our commitment is to provide our customers the very best after sales service.

Therefore, we are ready at Babcock Valves to supply a full range of guaranteed spare parts for our entire product range, covering all of our products, both old and new designs.

Our specialized technical staff is available for on-site maintenance and/or technical support such us plant ́s shutdown maintenance.

In addition to this, we provide analysis & trouble-shooting solutions to establish the causes of valve failures, valve accessories, related technical equipment, customized maintenance proposals, valve type selection, design alternatives advice, assessment of pipeline and fluid influence over valves and technical advice to improve valve operation.

Finally, training on Product Use & Maintenance for professionals is also into our abilities.

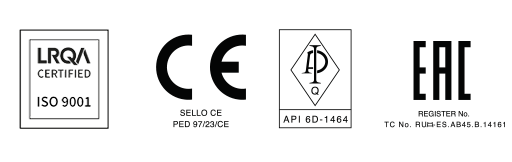

QUALITY AND CERTIFICATIONS

To guarantee high levels of quality for all of our products, our Quality Assurance Department implements a rigorous control and testing system throughout the manufacturing process. Moreover, Babcock Valves keeps an operational quality control and assurance manual that enables us to maintain optimum quality levels.

All of our products are tested during the design phase and after assembly, prior to shipment. Testing includes cryogenic tests, hot cycle tests, multi-axis vibration tests, aging tests, flow and pressure tests, seismic resistance tests, valve hammer-impact tests, actuator tests and others.

Quality Policy

Our Quality Policy, according to the Standard UNE-EN ISO 9001, API Spec. Q1 and UNE 73401, can be downloaded here.

Our valves are designed, manufactured and inspected, in accordance with the most relevant international standards, such as:

API

American Petroleum Institute

ANSI

American National Standards Institute

AWWA

American Water Works Association

DIN

Deutsche Norm

JIS

Japanese Industrial Standards

BS

British Standards

AFNOR

Association Française de Normalisation

MSS

Manufacturers Standardization Society

ISO

International Standards Organization

UNE

Spanish Standard

EAC

Eurasian Conformity

BABCOCK VALVES S.A.

ADDRESS

P.E. Abra Industrial, Parcela 1.5.6 – 48530 Ortuella (Bizkaia) Spain

TELEPHONE

(+34) 944 536 423

FAX

(+34) 944 535 739

Inquiry form

You can send us any question of your interest.

We will get back to you as soon as possible.

Legal disclosures

Cookies policy

Privacy statement