News and information

Valve manufacturing: the importance of painting considering operations within corrosive environments

In the realm of valve manufacturing, the significance of the painting process is paramount, particularly when...

Dimensional control of an angle globe valve body

Dimensional control of an angle globe valve body. Size 10″, rating 2500#, material A351 CF8C Pressure Seal design.

Valve painting process

Our painting process is carefully structured to include two distinct coats, each tailored to meet stringent client specifications.

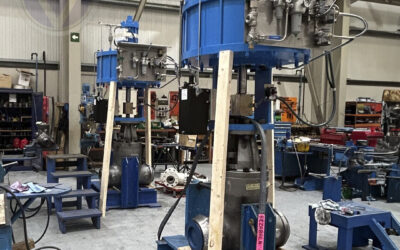

Nuclear certified Wedge Gate Valves

We are in the process of manufacturing a pair of complete spare valves for the Almaraz Nuclear Power Plant

Gland flange of a Parallel Slide Gate Valve

Assembly of the Gland and Gland Flange, integral components of the valve system that ensure the highest sealing efficiency and prevent any potential leakage through the stem.

20” class 300# flanged Angle Valve

Flanged angle valves have their inlet and outlet ports at an angle, typically 90 degrees, and are used for regulating the flow of fluids.

Advantages of Pressure Seal Bonnets in Gate valves

The advanced design of pressure seal bonnets significantly enhances valve performance, especially in high-pressure environments

Evolution of our 16” 4500# Parallel Slide Pressure Seal Gate Valve

Parallel Slide Pressure Seal Gate Valve, crafted from A182 F92 forged material, right from its inception at our facilities in Bilbao.

Expanding Our Offerings: Supplying UL/FM Approved Gate Valves

UL/FM approved gate valves and post indicators, specifically designed for outdoor fire protection applications

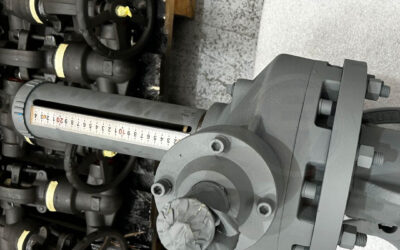

Valve Position Indicator: A Critical Aspect for Precision Flow Control

The ability to ascertain the valve’s position at a glance is crucial in some types of valves.

Babcock Valves’ Advanced Testing for the Nuclear Industry

Babcock Valves is once again partnering with the Spanish Nuclear Industry

Hydrotest for the Nuclear Classified ASME Section III, Subsection NB valve

This DN50 (2″) valve, conforming to ANSI Class 1500#, belongs to the Bellows Seal Y-Pattern Globe Valve category.

Two Bellows Seal Y-Pattern globe valves for Cofrentes Nuclear Power Plant

Presenting a pivotal supply update as we furnish two Bellows Seal Y-Pattern globe valves designated for installation at the Cofrentes Nuclear Power Plant

Bellows Seal valves: the art of zero leakage

Currently, we are manufacturing seismic-qualified variants of Bellows seal valves designed in accordance with ASME Section III for a Nuclear Power Plant. Before providing a glimpse into our workshop, please find below a concise introduction to these specialized...

Performing a Hydrotest in our mid-size test bench

At Babcock Valves, each testing phase is a testament to our unwavering commitment to quality assurance and precision engineering.

IBD valves in steam boiler systems

At Babcock Valves, we emphasize the meticulous design and testing of components like the IBD valve, ensuring optimal performance

Collaborative workshop efforts

Our commitment to adaptability and teamwork is evident, reflecting the dedication and involvement of our esteemed crew.

High-Pressure Gate Valves with pneumatic instrumentation

The precision in assembly aligns with stringent quality standards, ensuring optimal performance.

MORE NEWS

Assembling a Parallel Slide Gate Valve

In a recent update on our operations, we provided an insight into the meticulous assembly process of a robust 16" 4500# A182 F92 Parallel Slide Gate Valve. Today, we delve deeper into the features that make Parallel Slide Gate Valves indispensable in various...

Valve’s heat treatments

Here, we delve into the lapping process of a formidable 16” 4500# A182 F92 Parallel Slide Gate Valve currently in our fabrication lineup. Upon closer inspection, the valve's appearance has undergone a transformation, the vibrant color giving way to a more subdued hue....

Strainers and Steam traps

In our diverse portfolio of offerings, we extend our expertise beyond the conventional to include the fabrication and supply of Strainers and Steam traps. One recent example is an 8” ANSI Class 600# Strainer designed for installation as a FWHTR Recirculation Pump...

Remote valve testing

In the world of industrial valve testing, getting everyone on the same page can be a real puzzle. You've got the customer, the EPC contractor, the end user, and a bunch of inspection agencies – it's a juggling act. But, thanks to the tech tools we've all gotten used...

Parallel Slide Gate valve during the assembly process

Detail of a 16" 4500# A182 F92 Parallel Slide Gate valve during the assembly process. Here we can see the single wedge with both discs, disc Retainers and Stem (the spring is already inside). Parallel Slide Gate valves are an alternative to double disc valves, having...

Pressure seal bonnet: Swing Check valve at our medium test bench

We are going to welcome the new year with the image of this DN350 (14") ANSI Class 2500# Swing Check valve, with pressure seal bonnet, designed according to ASME B16.34, performing a hydrotest in our medium test bench. The pressure seal design creates a tight seal...

Dimensional control of a valve

At Babcock Valves we learned from our experience that any small detail on any part of a valve is critical to ensure the proper functioning of the whole valve. Here we can see the process of reception and dimensional control of two wedges for a 6" 2500# Pressure Seal...

Happy holydays!!!

In-house machining

We showed you in a prior post some actuator driving bushes ready to be internally machined. Just the valve stem and the actuator driving bush machining will define the valve operation time in the ON-OFF valves and the regulation precision level in all flow control...

Triple Eccentric Butterfly valve being tested

Here we have, in our medium-size test bench (a 450 Tons one) a Triple eccentric Butterfly valve being tested. Rating according to ANSI Class 2500#; stainless steel body (ASTM A351 CF10 casting); trim no.12 (316/hard-faced), metal to metal seating, shafts in Stainless...

Newborn twin valves

These twin check valve sisters begin one of the most amazing one: the assembly process

Valve body inspection

Here we have a DN65 (2 ½”) ANSI Class 2500# High Alloy A217 C12A swing check valve during body inspection, performing a PT test. Valve body inspections help ensure compliance with industry standards and regulations. Valves are often subjected to specific design codes,...

Valve testing: an important production stage

At Babcock Valves all valves are important: nuclear-qualified valves with ASME Section III design, Low Emission Bellows Seal valves Helium tested, Steam Extraction Quick Closing Check valves for turbine protection, Instrumented valves both MOV, AOV or Hydraulically...

Valve bypass installation stage

Valve bypass installation, workshop detail: two 16” forged bodies in equalizing pipe with integral bypass installation stage, and behind, a gate valve, DN250 PN100, in lapping process. Bypasses in valves are specialized features designed to provide a controlled flow...

Testing a Globe Valve for a HRSG in Vietnam

In our test bench, we are testing a 1 1/2" 4500# High Alloy High Pressure A182 F92 Globe Valve. As per ASME B16.34 and API 598, we perform the hydrotest at 1164 bar/16875 psig. The valve description is 'HP SH 1 Drain Manifold Drain Inching MOV', and will be shortly...

Actuator driving nuts

Actuator driving nuts can include a double start system in order to reduce the valve operating time.

𝗧𝗲𝘀𝘁𝗶𝗻𝗴 𝗮 𝗕𝗲𝗹𝗹𝗼𝘄𝘀 𝗦𝗲𝗮𝗹 𝗚𝗮𝘁𝗲 𝘃𝗮𝗹𝘃𝗲

Bellows seal gate valves are a specialized type of gate valve designed for industrial applications where leakage prevention is critical.

Packing with care

In the valve industry, packaging plays a crucial role beyond merely containing and protecting products.

𝗜𝗻𝘀𝗽𝗲𝗰𝘁𝗶𝗼𝗻 𝗼𝗳 𝗻𝘂𝗰𝗹𝗲𝗮𝗿-𝗾𝘂𝗮𝗹𝗶𝗳𝗶𝗲𝗱 𝗴𝗮𝘁𝗲 𝘃𝗮𝗹𝘃𝗲

This image corresponds to an inspection with Iberdrola and SGS teams.

Quality from the inside out

A couple of weeks ago, we wrote about the dimensional inspection of a valve, which involves a process of verification of physical dimensions, tolerances, and many other critical measurements of a valve, and it implies its “guts” too. Valve internals, seat rings,...

Quality from the inside out

Several ago, we made a post talking about the dimensional inspection of a valve, which involves a process of verification of physical dimensions, tolerances, and many other critical measurements of a valve, and it implies its “guts” too. Valve internals, seat rings,...

Dimensional inspection of a valve

Dimensional inspection of a valve involves verifying and assessing the physical dimensions, tolerances, and other critical measurements of the valve components

Valve reconditioning

We do not only design and manufacture valves. We also recondition and repair valves damaged in severe processes. The use of high-temperature molten salts is essential in energy production, where they are used to replace heated oils as transfer fluid for solar thermal...

Punching above its weight

This small valve has several rather special technical features: Despite its small size, 2", it has a Parallel Slide design. Despite its rating, of 600#, it has a Pressure Seal design. Its working range is from Full vacuum to maximum pressure rating. Its...

Veery special valves and very special clients

Sometimes we manufacture very special valves, but most of the time, we supply standard valves for very special clients, but always meeting the highest quality standards. (Sorry for the tongue twister :P) Here we have a pretty group of wedge gate valves waiting to be...

Welcome to our testing area

Again a large package of motorized valves is to be shipped in the next days. Here we have all of them waiting for their turn to be tested (MOV performance and Hydrotest). Babcock valves has three different testing benches, and the one in the picture is considered one...

Small but very special…

Here we have just verified the casting process of the body of a critical swing check valve 2 1/2" 2500# in high alloy A217 C12A. HP DSH Spray Water Check valve with 560 Celsius and 220 bar design conditions. The final destination of this small beauty will be Vietnam....

Target Achieved!

In record time, as we were asked to. These two valves will be installed in Almaraz Nuclear Power Plant. They were needed on record time and we have met our client's target again. We are proud of supporting the Spanish Nuclear Industry since the 1970's. Safe and clean....

Original Spare Parts guaranteed

Here we have a 24" 300# Double Disc Double Wedge Gate Valve ready for dispatch. This unit has been manufactured with the special painting procedure for Petronas. It is a spare valve that is supplied ready to take the original actuator. At Babcock, we guarantee...

Manufacturing a Steam Extraction Check Valve

Here we can see the final stages of the manufacturing process of a Steam Extraction Check Valve 18" (DN450) and ANSI Class 600# in Alloy Steel A217 WC6. This unit will be assembled with a linear actuator. On the bolted bonnet, the marked numbers indicate the right...

Lapping procedures

Here we are lapping a 24" Gate Valve with Parallel Seats, in our facilities. In every metal-to-metal seal in our valves, we must ensure a perfect closure. The quality of the finish of the machining between the seat rings and the discs must be perfect (mirror shape). ...

Double Disc Gate Valve assembly process

After the end of the lapping process, we begin with the valve assembly. In this video, you can find a better view of what a Double Wedge Double Disc valve, with parallel seats, is. It is a really smart and reliable design, but not too many manufacturers have the...

Double Disc Gate Valve design

Here we can see the details of our double disc, double wedge, and double seat gate valve design. This unique design guarantees a reliable operation under the most severe conditions of service, as it is proven by hundreds of units, working in some Main Steam Lines and...

Babcock Valves painting/coating area

Babcock valves have their own painting/coating area in our facilities at Biscay. Painting valves is an important process that involves applying a protective coating to the surface of valves to prevent corrosion and other forms of damage. The type of paint used for...

Trunnion Mounted Ball Valve with a Single-Acting fail-to-close actuator

In this picture, we can see a trunnion-mounted ball Valve with a Single-Acting fail-to-close pneumatic actuator attached. Trunnion Mounted Ball Valves are quarter-turn from open to close, assuring a fast response. The ball is fixed to a bearing at the bottom as well...

Manufacture of two Paraqllel Slide GAte Valves for a Combined Cycle Power Plant in Asia

We are manufacturing two 16" 4500# Parallel Slde Gate valves in A182 F92 High Alloy material. These valves will be installed in the Main Steam line of the Heat Recovery Steam Generator of a Combined Cycle Power Plant in Asia, with a total combined capacity of 1.5GW. ...

Performing the hydrotest of an 8″ Gate Valve

Here we have an 8” (DN200) ANSI Class 2500 Gate valve at one of the testing benches of our workshop, in Bizkaia, performing a hydrotest. The valve is made in Alloy Steel A217 WC9, capable of working in high-pressure and temperature environments. This unit is...

Y-pattern Stop-Check valve with motorized actuator

Here we have a Y-Pattern motorized Stop-Check valve. This kind of equipment is a combination of a globe valve and a check valve, which allows it to perform both functions. They are typically used in applications where it is important to prevent the reverse flow of...

Assembling an actuator for a QCNRV

Here we have one of our technicians adjusting some pieces in order to assemble an external linear pneumatic actuator for one pneumatically operated free swinging check valve. This is a very usual process in our workshop. We supply Quick Closing Non-Return Valves both...

Zero leakage Globe Valve

New SA105 1" 1500# Kerotest Zero Leakage globe valve manufactured by Babcock Valves in our factory in Bilbao. It is an ASME Section III Class I classified valve for a Nuclear Power Plant located in Catalonia. Zero Leakage valves are a type of valve that is designed to...

Assembly process of two Gate Valves

Here we are starting with the assembly process of two twin valves for a Caribbean country. Those Gate Valves, 8", rating 2500# (as shown in the second picture) are manufactured in alloy steel A217 WC6, a type of low-alloy steel that contains chromium and molybdenum,...

CBD-IBD valves

Continuous Blow-Down and Intermittent Blow Down needle angle valves. These are angle-type valves with a needle-shaped trim in a Venturi diffuser. This kind of equipment is totally critical in controlling the concentrations of suspended TDS (dissolved solids) in the...

Non destructive examination on a nuclear valve

This beauty is small but important. We are working here on the body of a 3", 150# gate valve, manufactured in ASME material SA216 WCB for an ASME Section III nuclear classified valve. SA216 refers to the material specification set by the American Society of Mechanical...

Final destination: Dominican Republic

Here we have a 8” 2500# wedge gate valve in A217 WC6, on our welding area. Seat rings are ready to be welded, before and after proper Heat Treatments. A217 WC6 is often used in applications such as power generation, oil and gas refining, and chemical processing, where...

12″ MOV Globe valve 600#

Here we have at our workshop, and ready for being packaged, a 12” MOV bolted bonnet globe valve 600# mounting a motorized actuator from Bernard Controls Spain. Babcock Valves manufactures this kind of valve in sizes between 1/2” to 48” with an ANSI class from 150 to...

Chainwheel operated gate valves

Sometimes valves are installed in places that are difficult to access. When they are at a certain height, the manual operation of the valves is quite complicated. For these cases, valves with a chainwheel can be supplied. Here are a few of them. A Gate Valve brochure,...

0 leakage Y-pattern globe valves for nuclear power plants

In the 70s and 80s Babcock Wilcox Española supplied the Spanish Nuclear Power Plants with hundreds of '0 Leakage' Y-Pattern globe valves of Kerotest design. Today, we still supply them with some identical valves to those installed several decades ago. Here you can see...

Custom made Y-pattern valve

Body & Yoke casting reception for a specially custom-made Y-Pattern High Pressure (2500#) globe valve for a petrochemical complex in Assam (India). Special face-to-face dimension and special Venturi design (8"x6"x8"). Babcock always focuses on the customer's...

𝗙𝟵𝟭 𝗵𝗶𝗴𝗵 𝗮𝗹𝗹𝗼𝘆 𝗽𝗮𝗿𝗮𝗹𝗹𝗲𝗹 𝘀𝗹𝗶𝗱𝗲 𝗴𝗮𝘁𝗲 𝘃𝗮𝗹𝘃𝗲

Fabricating a 26″ 600# A182 F91 high alloy parallel slide gate valve.

Actuator assembly in a motor operated valve

Assembling the actuator in a 1 ½” 1500# MOV Globe Valve

BABCOCK VALVES S.A.

ADDRESS

P.E. Abra Industrial, Parcela 1.5.6 – 48530 Ortuella (Bizkaia) Spain

TELEPHONE

(+34) 944 536 423

FAX

(+34) 944 535 739

Inquiry form

You can send us any question of your interest.

We will get back to you as soon as possible.

Legal disclosures

Cookies policy

Privacy statement