Product Range

Code 99

Type: Concentric

Sizes: Up to 200″

ANSI Class: 150-600

Complying with the requirements of the industrial sector.

Concentric butterfly valves has a resilient rubber seal with a metallic disc, that is placed concentrically between the shaft center line and the disc center line.

This valve type is designed to have an optimal mix of structural stability, flow efficiency and effective sealing properties, taking advantage of its light weight manufacture, compact design, low maintenance and ease of operation.

Butterfly valves can be operated via quarter-turn hand levers, or via gear, electrical or pneumatic actuators..

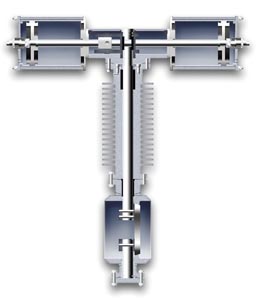

Code 100

Type: Double Eccentric

Sizes: Up to 200″

ANSI Class: 150-2500

A valve that meets the requirements of high pressure systems.

This high performance valves are characterized by its long lasting service life as well as for its low maintenance, due the reduced friction between the seal and the gasket.

In double eccentric butterfly valves, the disc is offset from the valve center line and also from the body center line of the valve. This creates a cam action during operation that lifts the seat out of the seal. This design offers excellent control of aperture, a reduced flow resistance, bubble tight shut-off, and a smooth operation.

Code 101

Type: Triple Eccentric

Sizes: Up to 200″

ANSI Class: 150-2500

A essential design in applications where bubble tight shut-off is required for zero leakage performance.

In triple eccentric butterfly valves, are either laminated or solid metal design. That prevents galling and scratches between the metal seat and the metal disc, due its unique design trough which the only time where the seal comes in contact with the seat is at the point of complete closure.

The firs eccentric is the offset between the shaft center line and the disc trunnion center line. The second one is the offset between the body center line and the disc center line, and the third and most relevant is the eccentric in the sealing. This kind of closing design is essential in applications where bubble-tight shut off is required, resulting in zero leakage performance.

This construction avoids the use of elastomers, typically affected by corrosion, and provides friction free stroking throughout the valve, extending valve’s life time, and reducing -even more- the characteristically low maintenance of butterfly valves..

Inquiry form

This site is protected by reCAPTCHA and the Google

Privacy Policy and

Terms of Service apply.

BABCOCK VALVES S.A.

ADDRESS

P.E. Abra Industrial, Parcela 1.5.6 – 48530 Ortuella (Bizkaia) Spain

TELEPHONE

(+34) 944 536 423

FAX

(+34) 944 535 739

Inquiry form

You can send us any question of your interest.

We will get back to you as soon as possible.

This site is protected by reCAPTCHA and the Google

Privacy Policy and

Terms of Service apply.

Legal disclosures

Cookies policy

Privacy statement