Axial flow check valves are a type of non return valve, designed to avoid the quick reverse of a flow in a pipe known as “water hammer” that may cause severe damage in the different equipments of a pipping system. This kind of valves close fast enough without creating excess pressure spikes, avoiding slamming.

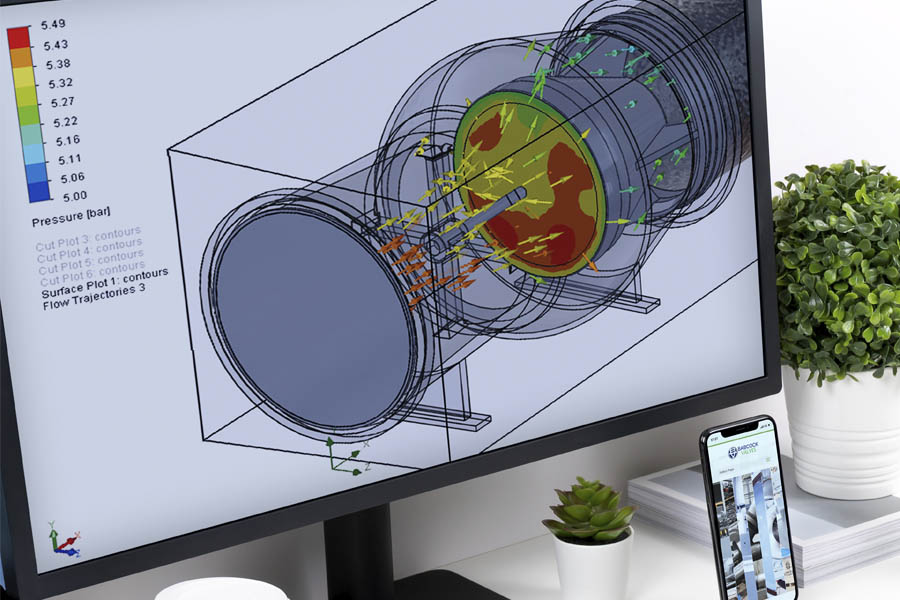

The streamlined design of the axial flow check valve permits its fully opening at low flows and fluid velocities, getting a low pressure drop. Its spring assisted system and metal-to-metal sealing features provides a non-slam closing and little maintenance.

Based on Venturi effect, the reduced flow area allows a fast full opening and the disc stays in position against its backstop on normal flow conditions. In a flow reduction situation, the spring reacts quickly, overcoming the fluid force and turning the disc back to a full close position with a short displacement. This system greatly reduces the reaction time, with a slam free response that protects critical elements of the pipeline.

This kind of valves can be used in multiple applications, like oil & gas, petrochemical, power generation, chemical… in any process in which water hammering is a real issue, and are an alternative to Quick Closing Non Return Valves, assisted with an actuator and used in those systems with higher protection requirements.

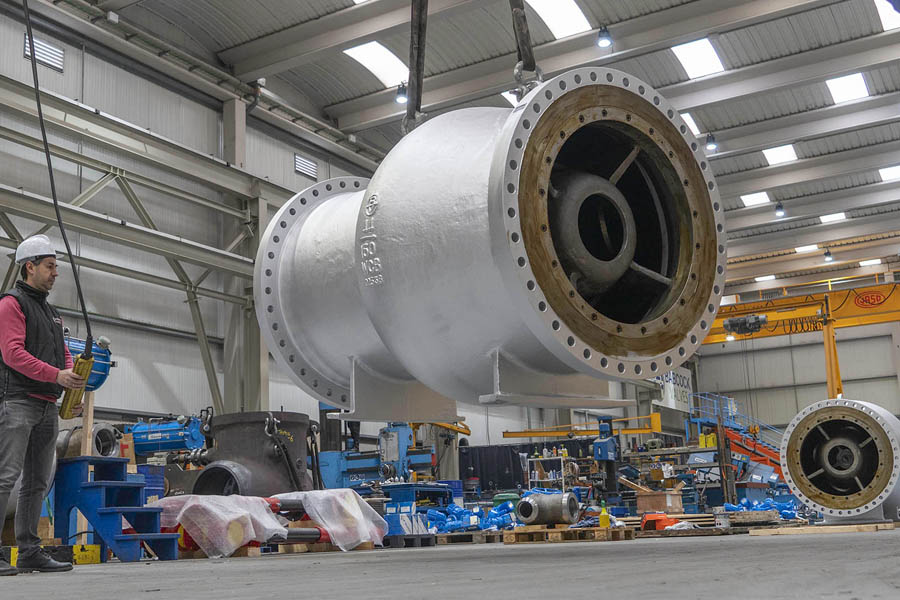

Babcock Valves designs and manufactures axial flow check valves in sizes from 6″ to 44″, with an ANSI class from 150 to 600. More information about our check valves can be find here.