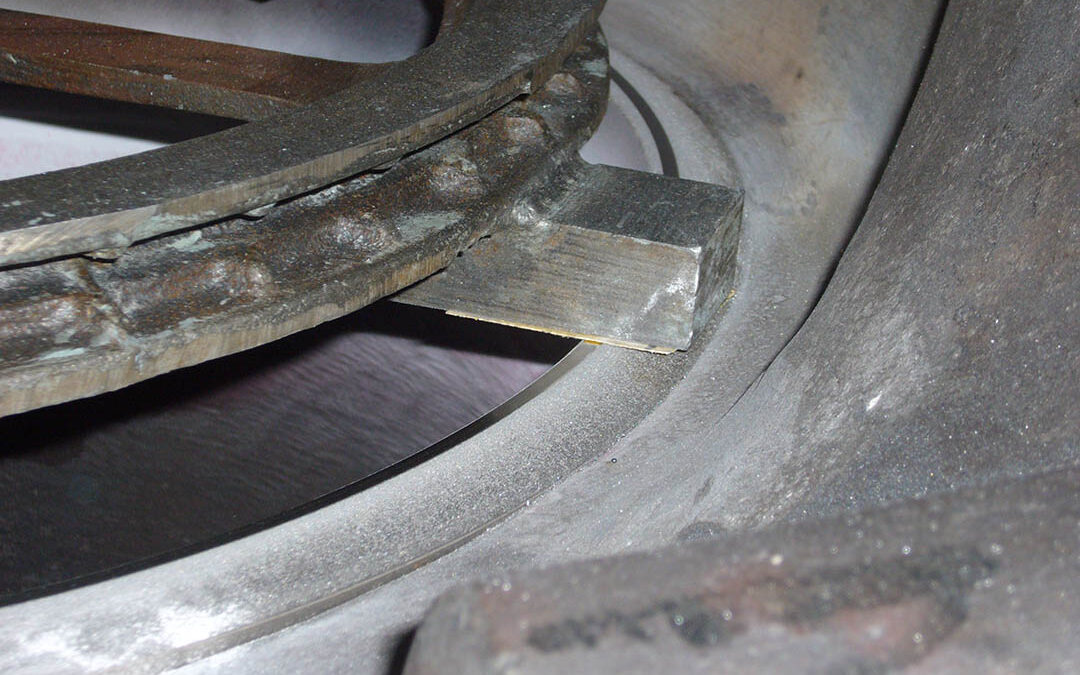

Here we are lapping a 24″ Gate Valve with Parallel Seats, in our facilities. In every metal-to-metal seal in our valves, we must ensure a perfect closure. The quality of the finish of the machining between the seat rings and the discs must be perfect (mirror shape).

Proper sealing between the valve seat and the valve disk is crucial in preventing leaks or loss of fluid flow through the valve. Without a properly lapped valve seat, there may be uneven pressure distribution between the valve seat and the valve disk, which can lead to leaks, increased wear, and reduced valve performance.

In addition to ensuring proper sealing, the lapping process can also help to extend the lifespan of the valve by reducing wear and minimizing the risk of damage to the valve seat or disk. Overall, the lapping process is a critical step in the manufacturing and maintenance of valves, helping to ensure optimal performance and longevity.

Visit us at https://babcockvalves.com/about-us/#MPP to learn more about our production procedures.

#ValveMaintenance, #ValveLapping, #ValveService #ValveManufacturing, #FluidControl, #ValvePerformance