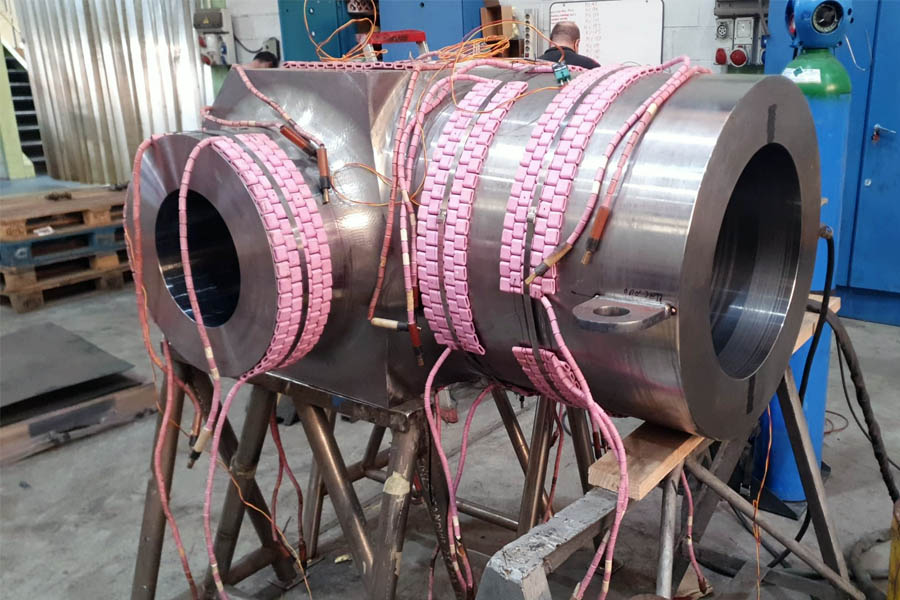

Babcock Valves has developed new welding procedures for F91 and F92 materials, avoiding direct flame heating on the forgings and using electrical heating resistances during the entire process of pre-heating, interpass maintenance and post-weld heat treatment. The process includes dehydrogenation between 280-300°C for 2 hours per 25 mm thickness with minimum of 2 hours.

The temperature is permanently monitored during the entire process. This guarantees that the material is 100% martensitic and the superficial and volumetric integrity of the same is perfectly controlled. For more information about our quality procedures and certifications, you can visit our quality section.