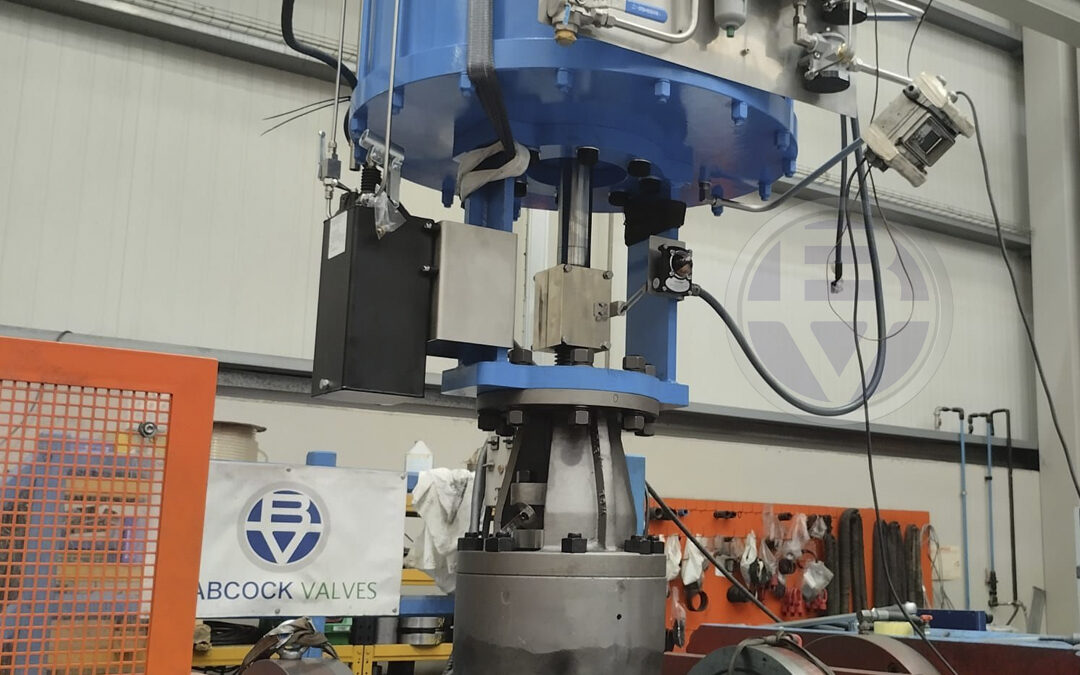

Step into the world of precision and collaboration as we showcase the meticulous process of hydrotesting a 10″ ANSI Class 2500# A217 WC9 alloy steel Wedge Gate valve in our state-of-the-art facility. Our commitment to excellence is evident in the seamless orchestration of tasks on our medium size test bench.

Hydrotesting involves subjecting the valve to rigorous conditions, such as a Shell Hydrotest at 647 bar for 300 seconds and a Seat Leaking test at 474 bar for 60 seconds. These procedures ensure the valve’s resilience under high pressures, validating its suitability for critical applications.

After this stage, we delve into the pneumatic actuator performance test, scrutinizing its precision in opening and closure at 340 bar. This test is integral to guaranteeing the valve’s functionality and reliability in real-world scenarios.

At Babcock Valves, each testing phase is a testament to our unwavering commitment to quality assurance and precision engineering. Every valve should meet and exceed industry standards, offering reliability in the most demanding environments.

You can find more information about our wedge gate valves at: https://babcockvalves.com/gate-valves/#wedge

#Hydrotesting #ValvePerformance #PrecisionEngineering #QualityAssurance #IndustrialTesting