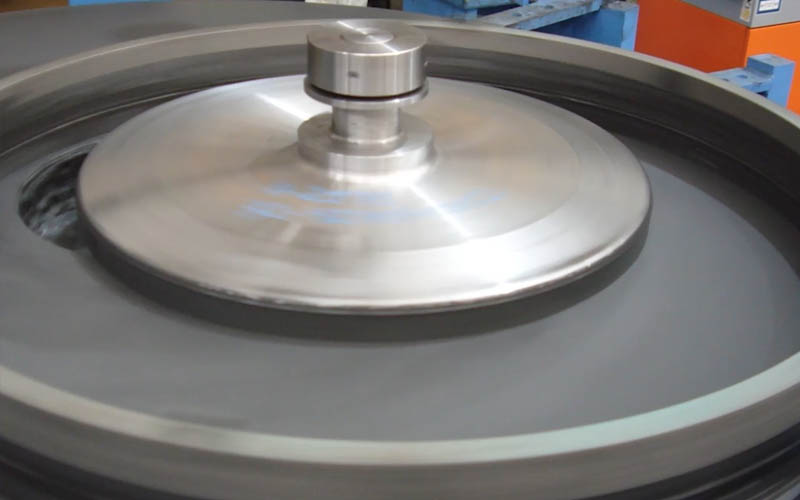

In this short video we can see the process of a valve seat ring lapping. Surfaces where metal is in direct contact with metal tend to wear hard. It is essential that the seal between the surfaces is absolutely tight to prevent leakage.

For more info about us and our production process, you can visit the about us section of this webpage.