In this post we have several news to share: from the detailed care we put on the final stages of our production process works, to the manufacture of a twelve tons Y-pattern globe valve or the precision techniques required to make some special valves.

The importance of the final stages of our production process

At Babcock we really do care about final stages of the manufacturing process of our valves. Testing, painting and properly packaging of the products is supervised under the meticulous control of our personnel. Every parcel must be approved by our Quality Assurance staff prior to leave our facilities.

You can read more about our production process at https://babcockvalves.com/about-us/

Precision machining

Precision machining is one of the most important steps in the manufacturing process of a high pressure valve like in the case of this big Y-Globe 24”, class 2500.

You can read more about our globe valves range of product at: https://babcockvalves.com/globe-valves/

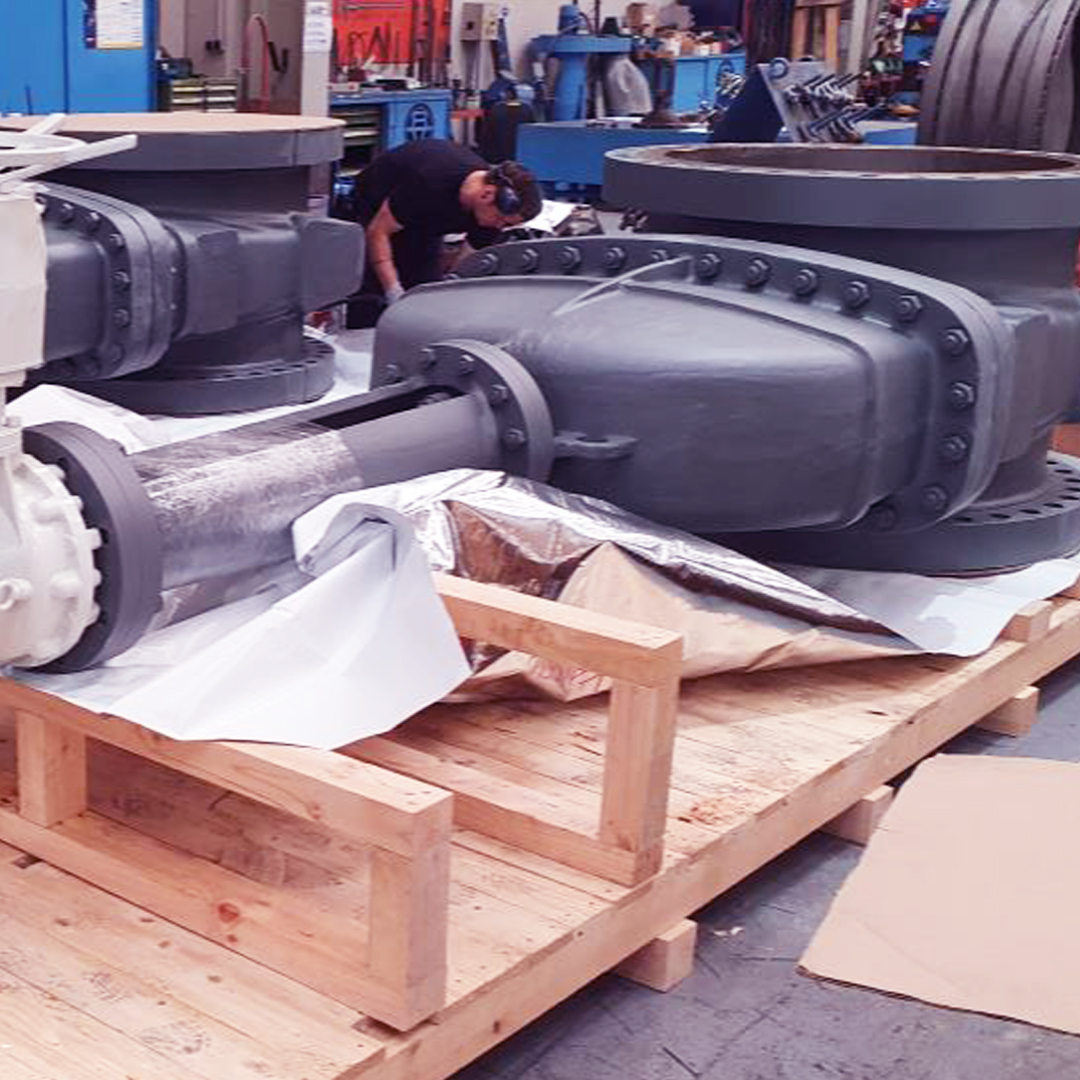

Package is a part of the product

Taking care of every detail. Quality starts from the engineering process to the final delivery. Detail of the packaging process of a special seaworthy packing for coastal area in Persian Gulf.

You can find more about our gate valves at: https://babcockvalves.com/gate-valves/

Twelve tons of Y-Pattern Globe Valve

Final assembly stage of a Y-Pattern Globe valve 24” 2500# in stainless steel (A351 CF8C). This 12 Ton valve will be installed in a Middle East refinery in its Residue Hydrotreating Unit (RHU).

Babcock Valves is one of the most reliable High Pressure Globe valve manufacturer specially focused on tailor made designs, large sizes and special materials.

You can find more information about our Y-pattern globe valves here: https://babcockvalves.com/globe-valves/#y-globe

You can download our Globe Valves brochure following this URL: https://babcockvalves.com/downloads